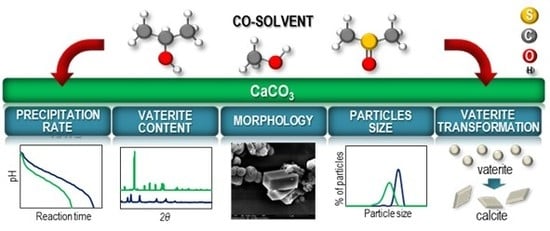

Precipitation and Transformation of Vaterite Calcium Carbonate in the Presence of Some Organic Solvents

Abstract

:1. Introduction

2. Materials and Methods

2.1. Reagents

2.2. Particle Preparation

2.3. Characterization of Particles

2.4. Absorption Test

3. Results and Discussion

3.1. The Course of the Precipitation

3.2. Characterization of the Particles

3.3. Interactions of Solvent Molecules with Vaterite and Calcite Particles

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Trushina, D.B.; Bukreeva, T.V.; Antipina, M.N. Size-Controlled Synthesis of Vaterite Calcium Carbonate by the Mixing Method: Aiming for Nanosized Particles. Cryst. Growth Des. 2016, 16, 1311–1319. [Google Scholar] [CrossRef]

- Chen, J.; Xiang, L. Controllable synthesis of calcium carbonate polymorphs at different temperatures. Powder Technol. 2010, 189, 64–69. [Google Scholar] [CrossRef]

- Flaten, E.M.; Seiersten, M.; Andreassen, J.P. Polymorphism and morphology of calcium carbonate precipitated in mixed solvents of ethylene glycol and water. J. Cryst. Growth 2009, 311, 3533–3538. [Google Scholar] [CrossRef]

- Zhang, L.; Yue, L.-H.; Wang, F.; Wang, Q. Divisive Effect of Alcohol−Water Mixed Solvents on Growth Morphology of Calcium Carbonate Crystals. J. Phys. Chem. B 2008, 112, 10668–10674. [Google Scholar] [CrossRef] [PubMed]

- Li, Q.; Ding, Y.; Li, F.; Xie, B.; Qian, Y. Solvothermal growth of vaterite in the presence of ethylene glycol, 1,2-propanediol and glycerin. J. Cryst. Growth 2002, 236, 357–362. [Google Scholar] [CrossRef]

- Choukrani, G.; Maharjan, B.; Park, C.H.; Kim, C.S.; Kurup Sasikala, A.R. Biocompatible superparamagnetic sub-micron vaterite particles for thermo-chemotherapy: From controlled design to in vitro anticancer synergism. Mater. Sci. Eng. C 2020, 106, 110226. [Google Scholar] [CrossRef] [PubMed]

- Vidallon, M.L.P.; Yu, F.; Teo, B.M. Controlling the Size and Polymorphism of Calcium Carbonate Hybrid Particles Using Natural Biopolymers. Cryst. Growth Des. 2020. [Google Scholar] [CrossRef]

- Trushina, D.B.; Bukreeva, T.V.; Kovalchuk, M.V.; Antipina, M.N. CaCO3 vaterite microparticles for biomedical and personal care applications. Mater. Sci. Eng. C 2014. [Google Scholar] [CrossRef]

- Mori, Y.; Enomae, T.; Isogai, A. Application of vaterite-type calcium carbonate prepared by ultrasound for ink jet paper. J. Imaging Sci. Technol. 2010, 54, 1–6. [Google Scholar] [CrossRef] [Green Version]

- Li, T.; Hu, Y.; Zhang, B. Biomineralization induced by Colletotrichum acutatum: A potential strategy for cultural relic bioprotection. Front. Microbiol. 2018, 9, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Ding, Y.; Liu, Y.; Ren, Y.; Yan, H.; Wang, M.; Wang, D.; Lu, X.Y.; Wang, B.; Fan, T.; Guo, H. Controllable synthesis of all the anhydrous CaCO3 polymorphs with various morphologies in CaCl2-NH3-CO2 aqueous system. Powder Technol. 2018, 333, 410–420. [Google Scholar] [CrossRef]

- Mori, Y.; Enomae, T.; Isogai, A. Preparation of pure vaterite by simple mechanical mixing of two aqueous salt solutions. Mater. Sci. Eng. C 2009, 29, 1409–1414. [Google Scholar] [CrossRef]

- Ukrainczyk, M.; Kontrec, J.; Babić-Ivančić, V.; Brečević, L.; Kralj, D. Experimental design approach to calcium carbonate precipitation in a semicontinuous process. Powder Technol. 2007, 171, 192–199. [Google Scholar] [CrossRef]

- Hou, W.; Feng, Q. Morphology and formation mechanism of vaterite particles grown in glycine-containing aqueous solutions. Mater. Sci. Eng. C 2006, 26, 644–647. [Google Scholar] [CrossRef]

- Udrea, I.; Capat, C.; Olaru, E.A.; Isopescu, R.; Mihai, M.; Mateescu, C.D.; Bradu, C. Vaterite synthesis via gas-liquid route under controlled pH conditions. Ind. Eng. Chem. Res. 2012, 51, 8185–8193. [Google Scholar] [CrossRef]

- Konopacka-Łyskawa, D.; Kościelska, B.; Łapiński, M. Precipitation of Spherical Vaterite Particles via Carbonation Route in the Bubble Column and the Gas-Lift Reactor. JOM 2019, 8185–8193. [Google Scholar] [CrossRef] [Green Version]

- Konopacka-Łyskawa, D.; Kościelska, B.; Karczewski, J.; Gołąbiewska, A. The influence of ammonia and selected amines on the characteristics of calcium carbonate precipitated from calcium chloride solutions via carbonation. Mater. Chem. Phys. 2017, 193, 13–18. [Google Scholar] [CrossRef]

- Deng, H.; Shen, X.C.; Wang, X.M.; Du, C. Calcium carbonate crystallization controlled by functional groups: A mini-review. Front. Mater. Sci. 2013, 7, 62–68. [Google Scholar] [CrossRef]

- Jaho, S.; Sygouni, V.; Rokidi, S.G.; Parthenios, J.; Koutsoukos, P.G.; Paraskeva, C.A. Precipitation of Calcium Carbonate in Porous Media in the Presence of n-Dodecane. Cryst. Growth Des. 2016, 16, 6874–6884. [Google Scholar] [CrossRef]

- Colfen, H. Precipitation of carbonates: Recent progress in controlled production of complex shapes. Curr. Opin. Colloid Interface Sci. 2003, 8, 23–31. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, Y.; Huang, X.; Wu, G. Biomimetic synthesis of calcium carbonate with different morphologies and polymorphs in the presence of bovine serum albumin and soluble starch. Mater. Sci. Eng. C 2017, 79, 457–464. [Google Scholar] [CrossRef]

- Sand, K.K.; Rodriguez-Blanco, J.D.; Makovicky, E.; Benning, L.G.; Stipp, S.L.S. Crystallization of CaCO3 in water-Alcohol mixtures: Spherulitic growth, polymorph stabilization, and morphology change. Cryst. Growth Des. 2012, 12, 842–853. [Google Scholar] [CrossRef]

- Konopacka-Łyskawa, D.; Kościelska, B.; Karczewski, J. Effect of some organic solvent—Water mixtures composition on precipitated calcium carbonate in carbonation process. J. Cryst. Growth 2015, 418, 25–31. [Google Scholar] [CrossRef]

- Wypych, G. Handbook of Solvents; Wypych, G., Ed.; ChemTec Publishing: Toronto, ON, Canada; New York, NY, USA, 2001; ISBN 1895198240. [Google Scholar] [CrossRef]

- Wada, N.; Kanamura, K.; Umegaki, T. Effects of carboxylic acids on the crystallization of calcium carbonate. J. Colloid Interface Sci. 2001, 233, 65–72. [Google Scholar] [CrossRef]

- Konopacka-Łyskawa, D.; Kościelska, B.; Karczewski, J. Controlling the size and morphology of precipitated calcite particles by the selection of solvent composition. J. Cryst. Growth 2017, 478, 102–110. [Google Scholar] [CrossRef]

- Natsi, P.D.; Rokidi, S.G.; Koutsoukos, P.G. Precipitation of Calcium Carbonate (CaCO3) in Water-Monoethylene Glycol Solutions. Ind. Eng. Chem. Res. 2019, 58, 4732–4743. [Google Scholar] [CrossRef]

- Kitamura, M. Controlling factor of polymorphism in crystallization process. J. Cryst. Growth 2002, 237–239, 2205–2214. [Google Scholar] [CrossRef]

- Chen, S.F.; Yu, S.H.; Hang, J.; Li, F.; Liu, Y. Polymorph discrimination of CaCO3 mineral in an ethanol/water solution: Formation of complex vaterite superstructures and aragonite rods. Chem. Mater. 2006, 18, 115–122. [Google Scholar] [CrossRef]

- Alan, G. Mass Transfer with Chemical Precipitation Reaction. Chem. Eng. Sci. 1991, 46, 1027–1033. [Google Scholar]

- Wang, K.; Wang, Y.J.; Chen, G.G.; Luo, G.S.; Wang, J.D. Enhancement of Mixing and Mass Transfer Performance with a Microstructure Minireactor for Controllable Preparation of CaCO3 Nanoparticles. Ind. Eng. Chem. Res. 2007, 6092–6098. [Google Scholar] [CrossRef]

- Reichardt, C. Solvents and Solvent Effects in Organic Chemistry, 3rd ed.; Wiley-VCH Publishers: Weinheim, Germany, 2003. [Google Scholar]

- Kan, A.T.; Fu, G.; Tomson, M.B. Effect of methanol on carbonate equilibrium and calcite solubility in a gas/methanol/water/salt mixed system. Langmuir 2002, 18, 9713–9725. [Google Scholar] [CrossRef]

- Luo, Q.; Feng, B.; Liu, Z.; Zhou, Q.; Zhang, Y.; Li, N. Experimental Study on Simultaneous Absorption and Desorption of CO2, SO2, and NOx Using Aqueous N-Methyldiethanolamine and Dimethyl Sulfoxide Solutions. Energy Fuels 2018, 32, 3647–3659. [Google Scholar] [CrossRef]

- Lam, R.K.; Smith, J.W.; Saykally, R.J. Communication: Hydrogen bonding interactions in water-alcohol mixtures from X-ray absorption spectroscopy. J. Chem. Phys. 2016, 144. [Google Scholar] [CrossRef] [Green Version]

- Dixit, S.; Crain, J.; Poon, W.C.K.; Finney, J.L.; Soper, A.K. Molecular Segregation in a Concnetrated Alcohol-Water Solution. Nature 2002, 416, 829–832. [Google Scholar] [CrossRef] [PubMed]

- Panuszko, A.; Bruździak, P.; Śmiechowski, M.; Stasiulewicz, M.; Stefaniak, J.; Stangret, J. DMSO hydration redefined: Unraveling the hydrophobic hydration of solutes with a mixed hydrophilic–hydrophobic characteristic. J. Mol. Liq. 2019, 294, 28–31. [Google Scholar] [CrossRef]

- Rezus, Y.L.A.; Bakker, H.J. Observation of immobilized water molecules around hydrophobic groups. Phys. Rev. Lett. 2007, 99, 1–4. [Google Scholar] [CrossRef]

- Hawlicka, E.; Swiatla-Wojcik, D. MD simulation studies of selective solvation in methanol-water mixtures: An effect of the charge density of a solute. J. Phys. Chem. A 2002, 106, 1336–1345. [Google Scholar] [CrossRef]

- Kunsági-Máté, S.; Iwata, K. Effect of cluster formation of solvent molecules on the preferential solvatation of anthracene in binary alcoholic solutions. Chem. Phys. Lett. 2009, 473, 284–287. [Google Scholar] [CrossRef]

- Kontoyannis, C.G.; Vagenas, N.V. Calcium carbonate phase analysis using XRD and FT-Raman spectroscopy. Analyst 2000, 125, 251–255. [Google Scholar] [CrossRef]

- Tai, C.Y.; Chen, F.B. Polymorphism of CaCO3 precipitated in a constant-composition environment. AIChE J. 1998, 44, 1790–1798. [Google Scholar] [CrossRef]

- Han, Y.; Fuji, M.; Shchukin, D.; Möhwald, H.; Takahashi, M. A new model for the synthesis of hollow particles via the bubble templating method. Cryst. Growth Des. 2009, 9, 3771–3775. [Google Scholar] [CrossRef]

- Rodriguez-Blanco, J.D.; Shaw, S.; Benning, L.G. The kinetics and mechanisms of amorphous calcium carbonate (ACC) crystallization to calcite, via vaterite. Nanoscale 2011, 3, 265–271. [Google Scholar] [CrossRef] [PubMed]

- Tobler, D.J.; Rodriguez Blanco, J.D.; Sørensen, H.O.; Stipp, S.L.S.; Dideriksen, K. Effect of pH on Amorphous Calcium Carbonate Structure and Transformation. Cryst. Growth Des. 2016, 16, 4500–4508. [Google Scholar] [CrossRef]

- Seo, K.; Han, C.; Wee, J.; Park, J.; Ahn, J. Synthesis of calcium carbonate in a pure ethanol and aqueous ethanol solution as the solvent. J. Cryst. Growth 2005, 276, 680–687. [Google Scholar] [CrossRef]

- Manoli, F.; Dalas, E. Spontaneous precipitation of calcium carbonate in the presence of ethanol, isopropanol and diethylene glycol. J. Cryst. Growth 2000, 218, 359–364. [Google Scholar] [CrossRef]

- Dickinson, S.R.; McGrath, K.M. Switching between kinetic and thermodynamic control: Calcium carbonate growth in the presence of a simple alcohol. J. Mater. Chem. 2003, 13, 928–933. [Google Scholar] [CrossRef]

- Konopacka-Łyskawa, D.; Czaplicka, N.; Kościelska, B.; Łapiński, M.; Gębicki, J. Influence of selected saccharides on the precipitation of calcium-vaterite mixtures by the CO2 bubbling method. Crystals 2019, 9, 117. [Google Scholar] [CrossRef] [Green Version]

- Popescu, M.A.; Isopescu, R.; Matei, C.; Fagarasan, G.; Plesu, V. Thermal decomposition of calcium carbonate polymorphs precipitated in the presence of ammonia and alkylamines. Adv. Powder Technol. 2014, 25, 500–507. [Google Scholar] [CrossRef]

| Solvent | Structure | Molar Mass (M) [g·mol−1] | Density (d) [g·cm−3] | Viscosity (η) [10−3 Pa·s] | Surface Tension (γ) [10−3 J·m−2] | Dielectric Constant (K) [−] | Dipole Moment (D) [−] |

|---|---|---|---|---|---|---|---|

| Water | H2O | 18.02 | 0.998 | 0.891 | 71.98 | 78.5 | 1.85 |

| DMSO | (CH3)2S=O | 78.13 | 1.092 | 1.996 | 43.00 | 46.7 | 3.90 |

| MeOH | CH3OH | 32.04 | 0.791 | 0.545 | 22.07 | 32.6 | 1.60 |

| iPrOH | (CH3)2CHOH | 60.1 | 0.785 | 2.073 | 18.30 | 19.9 | 1.66 |

| Solvent | Concentration (v/v) [%] | pHi | tr [min] | %Ca2+ |

|---|---|---|---|---|

| Control | 0 | 11.03 | 17.8 | 75% |

| DMSO | 5 | 10.98 | 18.8 | 66% |

| 10 | 10.96 | 19.2 | 68% | |

| 15 | 11.01 | 19.8 | 69% | |

| 20 | 10.97 | 20.1 | 71% | |

| MeOH | 5 | 11.04 | 16.0 | 69% |

| 10 | 11.00 | 16.5 | 68% | |

| 15 | 10.98 | 17.0 | 66% | |

| 20 | 10.98 | 17.4 | 64% | |

| iPrOH | 5 | 10.96 | 14.0 | 69% |

| 10 | 10.93 | 13.5 | 70% | |

| 15 | 10.94 | 13.0 | 71% | |

| 20 | 10.95 | 12.5 | 73% |

| Sample | Control | DMSO | MeOH | iPrOH | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Concentration (v/v) [%] | ||||||||||||||

| 0 | 5 | 10 | 15 | 20 | 5 | 10 | 15 | 20 | 5 | 10 | 15 | 20 | ||

| Incubation Time [h] | 0 | 94.6 | 92.0 | 90.0 | 90.1 | 86.5 | 94.6 | 93.6 | 90.7 | 90.5 | 94.4 | 92.0 | 88.4 | 81.5 |

| 1 | 79.6 | 73.6 | 71.4 | 78.6 | 78.9 | 60.0 | 57.2 | 50.4 | 59.2 | 74.9 | 52.1 | 44.9 | 24.4 | |

| 4 | 5.2 | 6.2 | 6.5 | 7.1 | 8.3 | 6.1 | 5.7 | 5.2 | 6.5 | 5.5 | 5.6 | 5.8 | 5.9 | |

| 24 | 4.6 | 5.6 | 5.9 | 6.0 | 6.1 | 5.7 | 5.4 | 5.0 | 5.7 | 5.3 | 5.3 | 5.2 | 5.2 | |

| Solvent | k’ | |

|---|---|---|

| Vaterite | Calcite | |

| DMSO | 2.58 | 2.21 |

| MeOH | 2.50 | 2.29 |

| iPrOH | 2.09 | 2.75 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Konopacka-Łyskawa, D.; Czaplicka, N.; Łapiński, M.; Kościelska, B.; Bray, R. Precipitation and Transformation of Vaterite Calcium Carbonate in the Presence of Some Organic Solvents. Materials 2020, 13, 2742. https://doi.org/10.3390/ma13122742

Konopacka-Łyskawa D, Czaplicka N, Łapiński M, Kościelska B, Bray R. Precipitation and Transformation of Vaterite Calcium Carbonate in the Presence of Some Organic Solvents. Materials. 2020; 13(12):2742. https://doi.org/10.3390/ma13122742

Chicago/Turabian StyleKonopacka-Łyskawa, Donata, Natalia Czaplicka, Marcin Łapiński, Barbara Kościelska, and Rafał Bray. 2020. "Precipitation and Transformation of Vaterite Calcium Carbonate in the Presence of Some Organic Solvents" Materials 13, no. 12: 2742. https://doi.org/10.3390/ma13122742

APA StyleKonopacka-Łyskawa, D., Czaplicka, N., Łapiński, M., Kościelska, B., & Bray, R. (2020). Precipitation and Transformation of Vaterite Calcium Carbonate in the Presence of Some Organic Solvents. Materials, 13(12), 2742. https://doi.org/10.3390/ma13122742