Effect of Bamboo Essential Oil on the Oxidative Stability, Microbial Attributes and Sensory Quality of Chicken Meatballs

Abstract

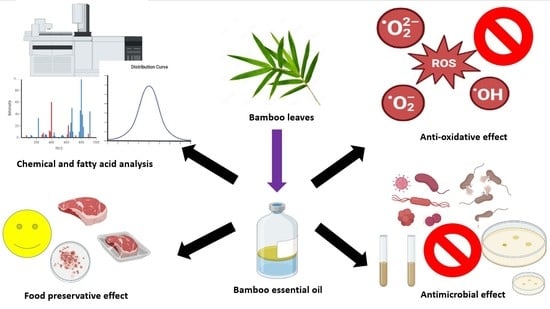

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Analysis of Bamboo Essential Oil

2.2.1. Total Phenolics Content

2.2.2. Total Flavonoid Content

2.2.3. Fatty Acid Analysis of BEO

2.3. In Vitro Antioxidant Potential of BEO

2.3.1. DPPH (2,2-diphenyl-2-picrylhydrazyl) Radical Scavenging Activity

2.3.2. Hydrogen Peroxide (H2O2) Scavenging Activity

2.3.3. Ferrous Ion Chelating Activity

2.3.4. Nitric Oxide Radical Scavenging Capacity

2.3.5. Hydroxyl Radical Scavenging Assay

2.3.6. Superoxide Anion Radical Scavenging

2.3.7. Total Antioxidant Activity by β-Carotene–Linoleic Acid Method

2.4. Assessment of In-Vitro Antimicrobial Activity of BEO

2.4.1. Preliminary Antimicrobial Screening of BEO against Microbial Pathogens In Vitro

2.4.2. In Vitro Minimum Inhibitory Concentration (MIC) and Minimum Biocidal Concentration (MBC)

2.5. Assessment of In Situ Food Preservative Effect of BEO in Modified Meat System

2.5.1. Preparation of Cooked Meatballs

2.5.2. Analysis of Meat Samples

pH

Proximate Composition and Cooking Yield

Color Measurement

Instrumental Texture Analysis of Cooked Chicken Meatballs

Expressible Water

Thiobarbituric Acid Reactive Substances

Microbiological Analysis

Sensory Evaluation of Cooked Chicken Meatballs

2.6. Statistical Analysis

3. Results and Discussion

3.1. Total Phenolics, Flavonoids and Fatty Acids Content of BEO

3.2. In Vitro Antioxidant Activity of BEO

3.2.1. DPPH Radical Scavenging Activity

3.2.2. Hydrogen Peroxide (H2O2) Scavenging Activity

3.2.3. Ferrous Ion Chelating Activity

3.2.4. Nitric Oxide Radical Scavenging Activity

3.2.5. Hydroxyl Radical Scavenging Assay

3.2.6. Superoxide Anion Radical Scavenging

3.2.7. Total Antioxidant Activity by β-Carotene–Linoleic Acid Method

3.3. Antimicrobial Activity of BEO by Disc Diffusion Method

3.4. Determination of MIC and MBC of BEO

3.5. Incorporation of BEO in Chicken Meatballs

3.5.1. Effect of BEO on pH, Emulsion Stability, Cooking Yield and Proximate Composition

3.5.2. Effect of BEO on Textural Properties of Meatballs

3.6. Effect of BEO on Physico-Chemical and Microbiological Qualities of Chicken Meatballs

3.6.1. Effect of BEO on pH of Meatballs

3.6.2. Effect of BEO on TBARS Value of Meatballs

3.6.3. Effect of BEO on Color Values of Meatballs

3.6.4. Effect of BEO on Microbiological Changes in Meatballs

3.6.5. Effect of BEO on Sensory Attributes of Meatballs

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pellissery, A.J.; Vinayamohan, P.G.; Amalaradjou, M.A.R.; Venkitanarayanan, K. Spoilage Bacteria and Meat Quality. In Meat Quality Analysis: Advanced Evaluation Methods, Techniques, and Technologies; Academic Press: Cambridge, MA, USA, 2019; pp. 307–334. ISBN 9780128192337. [Google Scholar]

- Falowo, A.B.; Fayemi, P.O.; Muchenje, V. Natural Antioxidants against Lipid-Protein Oxidative Deterioration in Meat and Meat Products: A Review. Food Res. Int. 2014, 64, 171–181. [Google Scholar] [CrossRef] [PubMed]

- Das, A.K.; Nanda, P.K.; Chowdhury, N.R.; Dandapat, P.; Gagaoua, M.; Chauhan, P.; Pateiro, M.; Lorenzo, J.M. Application of Pomegranate By-Products in Muscle Foods: Oxidative Indices, Colour Stability, Shelf Life and Health Benefits. Molecules 2021, 26, 467. [Google Scholar] [CrossRef] [PubMed]

- Huang, X.; Ahn, D.U. Lipid Oxidation and Its Implications to Meat Quality and Human Health. Food Sci. Biotechnol. 2019, 28, 1275–1285. [Google Scholar] [CrossRef] [PubMed]

- Madane, P.; Das, A.K.; Nanda, P.K.; Bandyopadhyay, S.; Jagtap, P.; Shewalkar, A.; Maity, B. Dragon Fruit (Hylocereus Undatus) Peel as Antioxidant Dietary Fibre on Quality and Lipid Oxidation of Chicken Nuggets. J. Food Sci. Technol. 2020, 57, 1449–1461. [Google Scholar] [CrossRef] [PubMed]

- Das, A.K.; Nanda, P.K.; Madane, P.; Biswas, S.; Das, A.; Zhang, W.; Lorenzo, J.M. A Comprehensive Review on Antioxidant Dietary Fibre Enriched Meat-Based Functional Foods. Trends Food Sci. Technol. 2020, 99, 323–336. [Google Scholar] [CrossRef]

- Jongberg, S.; Lund, M.N.; Skibsted, L.H. Protein Oxidation in Meat and Meat Products. Challenges for Antioxidative Protection. In Global Food Security and Wellness; Springer: New York, NY, USA, 2017; pp. 315–337. ISBN 9781493964963. [Google Scholar]

- Das, A.K.; Nanda, P.K.; Das, A.; Biswas, S. Hazards and Safety Issues of Meat and Meat Products. Food Saf. Hum. Heal. 2019, 145–168. [Google Scholar] [CrossRef]

- Ramli, A.N.M.; Badrulzaman, S.Z.S.; Hamid, H.A.; Bhuyar, P. Antibacterial and Antioxidative Activity of the Essential Oil and Seed Extracts of Artocarpus Heterophyllus for Effective Shelf-Life Enhancement of Stored Meat. J. Food Process. Preserv. 2021, 45. [Google Scholar] [CrossRef]

- Zahid, M.A.; Seo, J.K.; Park, J.Y.; Jeong, J.Y.; Jin, S.K.; Park, T.S.; Yang, H.S. The Effects of Natural Antioxidants on Protein Oxidation, Lipid Oxidation, Color, and Sensory Attributes of Beef Patties during Cold Storage at 4 °C. Korean J. Food Sci. Anim. Resour. 2018, 38, 1029–1042. [Google Scholar] [CrossRef] [Green Version]

- Alfonzo, A.; Martorana, A.; Guarrasi, V.; Barbera, M.; Gaglio, R.; Santulli, A.; Settanni, L.; Galati, A.; Moschetti, G.; Francesca, N. Effect of the Lemon Essential Oils on the Safety and Sensory Quality of Salted Sardines (Sardina Pilchardus Walbaum 1792). Food Control 2017, 73, 1265–1274. [Google Scholar] [CrossRef] [Green Version]

- Sharma, H.; Mendiratta, S.K.; Agrawal, R.K.; Gurunathan, K.; Kumar, S.; Singh, T.P. Use of Various Essential Oils as Bio Preservatives and Their Effect on the Quality of Vacuum Packaged Fresh Chicken Sausages under Frozen Conditions. LWT -Food Sci. Technol. 2017, 81, 118–127. [Google Scholar] [CrossRef]

- El-Sayed, H.S.; Chizzola, R.; Ramadan, A.A.; Edris, A.E. Chemical Composition and Antimicrobial Activity of Garlic Essential Oils Evaluated in Organic Solvent, Emulsifying, and Self-Microemulsifying Water Based Delivery Systems. Food Chem. 2017, 221, 196–204. [Google Scholar] [CrossRef] [PubMed]

- dos Santos Rodrigues, J.B.; de Carvalho, R.J.; de Souza, N.T.; de Sousa Oliveira, K.; Franco, O.L.; Schaffner, D.; de Souza, E.L.; Magnani, M. Effects of Oregano Essential Oil and Carvacrol on Biofilms of Staphylococcus Aureus from Food-Contact Surfaces. Food Control 2017, 73, 1237–1246. [Google Scholar] [CrossRef]

- Pateiro, M.; Munekata, P.E.S.; Sant’Ana, A.S.; Domínguez, R.; Rodríguez-Lázaro, D.; Lorenzo, J.M. Application of Essential Oils as Antimicrobial Agents against Spoilage and Pathogenic Microorganisms in Meat Products. Int. J. Food Microbiol. 2021, 337. [Google Scholar] [CrossRef] [PubMed]

- Hematizad, I.; Khanjari, A.; Basti, A.A.; Karabagias, I.K.; Noori, N.; Ghadami, F.; Gholami, F.; Teimourifard, R. In Vitro Antibacterial Activity of Gelatin-Nanochitosan Films Incorporated with Zataria Multiflora Boiss Essential Oil and Its Influence on Microbial, Chemical, and Sensorial Properties of Chicken Breast Meat during Refrigerated Storage. Food Packag. Shelf Life 2021, 30. [Google Scholar] [CrossRef]

- Chongtham, N.; Bisht, M.S.; Santosh, O.; Bajwa, H.K.; Indira, A. Mineral Elements in Bamboo Shoots and Potential Role in Food Fortification. J. Food Compos. Anal. 2021, 95, 103662. [Google Scholar] [CrossRef]

- Chongtham, N.; Bisht, M.S.; Bajwa, H.K.; Santosh, O. Bamboo: A Rich Source of Natural Antioxidants and Its Applications in the Food and Pharmaceutical Industry. Trends Food Sci. Technol. 2018, 77, 91–99. [Google Scholar] [CrossRef]

- Lu, B.; Xia, D.; Huang, W.; Wu, X.; Zhang, Y.; Yao, Y. Hypolipidemic Effect of Bamboo Shoot Oil (P. Pubescens) in Sprague-Dawley Rats. J. Food Sci. 2010, 75. [Google Scholar] [CrossRef]

- Sánchez-Rangel, J.C.; Benavides, J.; Heredia, J.B.; Cisneros-Zevallos, L.; Jacobo-Velázquez, D.A. The Folin–Ciocalteu Assay Revisited: Improvement of Its Specificity for Total Phenolic Content Determination. Anal. Methods 2013, 5, 5990. [Google Scholar] [CrossRef]

- Ti, H.; Zhang, R.; Li, Q.; Wei, Z.; Zhang, M. Effects of Cooking and in Vitro Digestion of Rice on Phenolic Profiles and Antioxidant Activity. Food Res. Int. 2015, 76, 813–820. [Google Scholar] [CrossRef]

- AOAC. International AOAC Official Method 969.33. AOAC Int. 2000, 41, 19–61. [Google Scholar]

- Rahman, M.M.; Islam, M.B.; Biswas, M.; Khurshid Alam, A.H.M. In Vitro Antioxidant and Free Radical Scavenging Activity of Different Parts of Tabebuia Pallida Growing in Bangladesh. BMC Res. Notes 2015, 8. [Google Scholar] [CrossRef] [PubMed]

- Ruch, R.J.; Cheng, S.J.; Klaunig, J.E. Prevention of Cytotoxicity and Inhibition of Intercellular Communication by Antioxidant Catechins Isolated from Chinese Green Tea. Carcinogenesis 1989, 10, 1003–1008. [Google Scholar] [CrossRef] [PubMed]

- Brand-Williams, W.; Cuvelier, M.E.; Berset, C. Use of a Free Radical Method to Evaluate Antioxidant Activity. LWT-Food Sci. Technol. 1995, 28, 25–30. [Google Scholar] [CrossRef]

- Makhija, I.K.; Aswatha Ram, H.N.; Shreedhara, C.S.; Vijay Kumar, S.; Devkar, R. In Vitro Antioxidant Studies of Sitopaladi Churna, a Polyherbal Ayurvedic Formulation. Free Radic. Antioxid. 2011, 1, 37–41. [Google Scholar] [CrossRef] [Green Version]

- Zhou, J.; Yang, Q.; Zhu, X.; Lin, T.; Hao, D.; Xu, J. Antioxidant Activities of Clerodendrum Cyrtophyllum Turcz Leaf Extracts and Their Major Components. PLoS ONE 2020, 15, e0234435. [Google Scholar] [CrossRef]

- Der Duh, P.; Tu, Y.Y.; Yen, G.C. Antioxidant Activity of Water Extract of Harng Jyur (Chrysanthemum Morifolium Ramat). Lwt 1999, 32, 269–277. [Google Scholar] [CrossRef]

- Dapkevicius, A.; Venskutonis, R.; van Beek, T.A.; Linssen, J.P.H. Antioxidant Activity of Extracts Obtained by Different Isolation Procedures from Some Aromatic Herbs Grown in Lithuania. J. Sci. Food Agric. 1998, 77, 140–146. [Google Scholar] [CrossRef]

- Al-Saikhan, M.S.; Howard, L.R.; Miller, J.C. Antioxidant Activity and Total Phenolics in Different Genotypes of Potato (Solanum Tuberosum, L.). J. Food Sci. 1995, 60, 341–343. [Google Scholar] [CrossRef]

- Sfeir, J.; Lefrançois, C.; Baudoux, D.; Derbré, S.; Licznar, P. In Vitro Antibacterial Activity of Essential Oils against Streptococcus Pyogenes. Evid.-Based Complement. Altern. Med. 2013, 2013, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Elshikh, M.; Ahmed, S.; Funston, S.; Dunlop, P.; McGaw, M.; Marchant, R.; Banat, I.M. Resazurin-Based 96-Well Plate Microdilution Method for the Determination of Minimum Inhibitory Concentration of Biosurfactants. Biotechnol. Lett. 2016, 38, 1015–1019. [Google Scholar] [CrossRef] [Green Version]

- Qureshi, K.A.; Bholay, A.D.; Rai, P.K.; Mohammed, H.A.; Khan, R.A.; Azam, F.; Jaremko, M.; Emwas, A.H.; Stefanowicz, P.; Waliczek, M.; et al. Isolation, Characterization, Anti-MRSA Evaluation, and in-Silico Multi-Target Anti-Microbial Validations of Actinomycin X2 and Actinomycin D Produced by Novel Streptomyces Smyrnaeus UKAQ_23. Sci. Rep. 2021, 11. [Google Scholar] [CrossRef] [PubMed]

- AOAC. Official Methods of Analysis, 16th ed.; Association of Official Analytical Chemists: Washington, DC, USA, 1995. [Google Scholar]

- Jauregui, C.A.; Regenstein, J.M.; Baker, R.C. A Simple Centrifugal Method for Measuring Expressible Moisture, A Water-Binding Property of Muscle Foods. J. Food Sci. 1981, 46, 1271. [Google Scholar] [CrossRef]

- Witte, V.C.; Krause, G.F.; Bailey, M.F. A New Extraction Method for Determining 2-Thiobarbituric Acid Values of Pork and Beef during Storage. J. Food Sci. 1970, 35, 582–585. [Google Scholar] [CrossRef]

- APHA. Compendium of Methods for The Microbiological Examination of Foods; American Public Health Association: Washington DC, USA, 2001. [Google Scholar]

- Das, A.K.; Rajkumar, V.; Nanda, P.K.; Chauhan, P.; Pradhan, S.R.; Biswas, S. Antioxidant Efficacy of Litchi (Litchi Chinensis Sonn.) Pericarp Extract in Sheep Meat Nuggets. Antioxidants 2016, 5, 16. [Google Scholar] [CrossRef]

- Nirmala, C.; Bisht, M.S.; Laishram, M. Bioactive Compounds in Bamboo Shoots: Health Benefits and Prospects for Developing Functional Foods. Int. J. Food Sci. Technol. 2014, 49, 1425–1431. [Google Scholar] [CrossRef]

- Sharma, V.; Devi, T.P.; Nirmala, C.; Bisht, M.S. Bamboo Shoots: An Untapped Source of Essential Nutrients and Bioactive Compounds. Third Int. Conf. Res. Dev. Appl. Sci. Eng. Manag. 2018, 7, 247–255. [Google Scholar]

- Ribeiro-Santos, R.; Andrade, M.; Sanches-Silva, A.; de Melo, N.R. Essential Oils for Food Application: Natural Substances with Established Biological Activities. Food Bioprocess Technol. 2018, 11, 43–71. [Google Scholar] [CrossRef]

- Singh, G.; Maurya, S.; DeLampasona, M.P.; Catalan, C.A.N. A Comparison of Chemical, Antioxidant and Antimicrobial Studies of Cinnamon Leaf and Bark Volatile Oils, Oleoresins and Their Constituents. Food Chem. Toxicol. 2007, 45, 1650–1661. [Google Scholar] [CrossRef]

- Park, E.J.; Jhon, D.Y. The Antioxidant, Angiotensin Converting Enzyme Inhibition Activity, and Phenolic Compounds of Bamboo Shoot Extracts. LWT-Food Sci. Technol. 2010, 43, 655–659. [Google Scholar] [CrossRef]

- Neményi, A.; Stefanovitsné-Bányai, É.; PéK, Z.; Hegedus, A.; Gyuricza, C.; Barócsi, Z.; Helyes, L. Total Antioxidant Capacity and Total Phenolics Content of Phyllostachys Taxa Shoots. Not. Bot. Horti Agrobot. Cluj-Napoca 2015, 43, 64–69. [Google Scholar] [CrossRef] [Green Version]

- Yang, H.; Zhou, C.; Wu, F.; Cheng, J. Effect of Nitric Oxide on Browning and Lignification of Peeled Bamboo Shoots. Postharvest Biol. Technol. 2010, 57, 72–76. [Google Scholar] [CrossRef]

- Feng, X.; Song, Z.; Wang, J.; Fang, J. Comparison of Total Flavonoids Content in Different Bamboo Shoots and Different Parts. E3S Web Conf. 2021, 233, 02033. [Google Scholar] [CrossRef]

- Lu, B.; Cai, H.; Huang, W.; Wu, X.; Luo, Y.; Liu, L.; Zhang, Y. Protective Effect of Bamboo Shoot Oil on Experimental Nonbacterial Prostatitis in Rats. Food Chem. 2011, 124, 1017–1023. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, J.; Wang, D.; Ye, F.; He, Y.; Hu, Z.; Zhao, G. A Systematic Review on the Composition, Storage, Processing of Bamboo Shoots: Focusing the Nutritional and Functional Benefits. J. Funct. Foods 2020, 71, 104015. [Google Scholar] [CrossRef]

- Tao, C.; Wang, Y.; Zhang, X.; Li, L.; Wu, Y.; Han, X.; Jiang, X.; Lv, Z. Bamboo Leaves Essential Oils. BioResources 2019, 14, 1419–1434. [Google Scholar] [CrossRef]

- Tao, C.; Wu, J.; Liu, Y.; Liu, M.; Yang, R.; Lv, Z. Antimicrobial Activities of Bamboo (Phyllostachys Heterocycla Cv. Pubescens) Leaf Essential Oil and Its Major Components. Eur. Food Res. Technol. 2018, 244, 881–891. [Google Scholar] [CrossRef]

- Tanaka, A.; Shimizu, K.; Kondo, R. Antibacterial Compounds from Shoot Skins of Moso Bamboo (Phyllostachys Pubescens). J. Wood Sci. 2013, 59, 155–159. [Google Scholar] [CrossRef]

- Syafiq, R.; Sapuan, S.M.; Zuhri, M.Y.M.; Ilyas, R.A.; Nazrin, A.; Sherwani, S.F.K.; Khalina, A. Antimicrobial Activities of Starch-Based Biopolymers and Biocomposites Incorporated with Plant Essential Oils: A Review. Polymers 2020, 12, 2403. [Google Scholar] [CrossRef]

- Ji, J.; Shankar, S.; Royon, F.; Salmieri, S.; Lacroix, M. Essential Oils as Natural Antimicrobials Applied in Meat and Meat Products—A Review. Crit. Rev. Food Sci. Nutr. 2021, 1–17. [Google Scholar] [CrossRef]

- Possas, A.; Posada-Izquierdo, G.D.; Pérez-Rodríguez, F.; Valero, A.; García-Gimeno, R.M.; Duarte, M.C.T. Application of Predictive Models to Assess the Influence of Thyme Essential Oil on Salmonella Enteritidis Behaviour during Shelf Life of Ready-to-Eat Turkey Products. Int. J. Food Microbiol. 2017, 240, 40–46. [Google Scholar] [CrossRef]

- Burt, S. Essential Oils: Their Antibacterial Properties and Potential Applications in Foods—A Review. Int. J. Food Microbiol. 2004, 94, 223–253. [Google Scholar] [CrossRef] [PubMed]

- Santosh, O.; Bajwa, H.K.; Bisht, M.S.; Chongtham, N. Antioxidant Activity and Sensory Evaluation of Crispy Salted Snacks Fortified with Bamboo Shoot Rich in Bioactive Compounds. Appl. Food Res. 2021, 1, 100018. [Google Scholar] [CrossRef]

- Santosh, O.; Bisht, M.S.; Chongtham, N. Functional Biscuits from Bamboo Shoots: Enrichment of Nutrients, Bioactive Compounds and Minerals in Bamboo Shoot Paste Fortified Biscuits Minerals in Bamboo Shoot Paste Fortified Biscuits. Int. J. Food Sci. Nutr. 2019, 4, 89–94. [Google Scholar]

- Singhal, P.; Satya, S.; Naik, S.N. Fermented Bamboo Shoots: A Complete Nutritional, Anti-Nutritional and Antioxidant Profile of the Sustainable and Functional Food to Food Security. Food Chem. Mol. Sci. 2021, 3, 100041. [Google Scholar] [CrossRef]

- Das, A.; Nath, D.R.; Kumari, S.; Saha, R. Effect of Fermented Bamboo Shoot on the Quality and Shelf Life of Nuggets Prepared from Desi Spent Hen. Vet. World 2013, 6, 419–423. [Google Scholar] [CrossRef]

- Amaral, D.M.F.; Bhargava, K. Essential Oil Nanoemulsions and Food Applications. Adv. Food Technol. Nutr. Sci. -Open J. 2015, 1, 84–87. [Google Scholar] [CrossRef]

- Mantzourani, I.; Daoutidou, M.; Dasenaki, M.; Nikolaou, A.; Alexopoulos, A.; Terpou, A.; Thomaidis, N.; Plessas, S. Plant Extract and Essential Oil Application against Food-Borne Pathogens in Raw Pork Meat. Foods 2022, 11, 861. [Google Scholar] [CrossRef]

- Reddy, D.M.; Reddy, G.V.B.; Mandal, P.K. Application of Natural Antioxidants in Meat and Meat Products—A Review. Food Nutr. J. 2018, 7. [Google Scholar] [CrossRef]

- Pateiro, M.; Bermúdez, R.; Lorenzo, J.; Franco, D. Effect of Addition of Natural Antioxidants on the Shelf-Life of “Chorizo”, a Spanish Dry-Cured Sausage. Antioxidants 2015, 4, 42–67. [Google Scholar] [CrossRef] [Green Version]

- Moraes-Lovison, M.; Marostegan, L.F.P.; Peres, M.S.; Menezes, I.F.; Ghiraldi, M.; Rodrigues, R.A.F.; Fernandes, A.M.; Pinho, S.C. Nanoemulsions Encapsulating Oregano Essential Oil: Production, Stability, Antibacterial Activity and Incorporation in Chicken Pâté. LWT -Food Sci. Technol. 2017, 77, 233–240. [Google Scholar] [CrossRef]

- Siewe, F.B.; Mbougueng, P.D.; Tatsadjieu, L.N.; Noumo, T.N.; Mbofung, C.M.F. The Potential Application of Syzygium Aromaticum and Cymbopogon Citratus Essential Oils as Natural Preservatives of Beef Patties. Food Nutr. Sci. 2015, 06, 374–385. [Google Scholar] [CrossRef] [Green Version]

- Sharma, H.; Mendiratta, S.K.; Agarwal, R.K.; Kumar, S.; Soni, A. Evaluation of Anti-Oxidant and Anti-Microbial Activity of Various Essential Oils in Fresh Chicken Sausages. J. Food Sci. Technol. 2017, 54, 279–292. [Google Scholar] [CrossRef] [PubMed]

- Madane, P.; Das, A.K.; Pateiro, M.; Nanda, P.K.; Bandyopadhyay, S.; Jagtap, P.; Barba, F.J.; Shewalkar, A.; Maity, B.; Lorenzo, J.M. Drumstick (Moringa Oleifera) Flower as an Antioxidant Dietary Fibre in Chicken Meat Nuggets. Foods 2019, 8, 307. [Google Scholar] [CrossRef]

- Thomas, R.; Jebin, N.; Barman, K.; Das, A. Quality and Shelf Life Evaluation of Pork Nuggets Incorporated with Fermented Bamboo Shoot (Bambusa Polymorpha) Mince. Meat Sci. 2014, 96, 1210–1218. [Google Scholar] [CrossRef] [PubMed]

- Kim, Y.A.; Park, S.; Park, Y.; Park, G.; Oh, S.; Choi, J. Effect of Addition of Fermented Soy Sauce on Quality Characteristics of Pork Patties during Refrigerated Storage. Foods 2022, 11, 1004. [Google Scholar] [CrossRef] [PubMed]

- Tomović, V.; Šojić, B.; Savanović, J.; Kocić-Tanackov, S.; Pavlić, B.; Jokanović, M.; Dordević, V.; Parunović, N.; Martinović, A.; Vujadinović, D. New Formulation towards Healthier Meat Products: Juniperus Communis l. Essential Oil as Alternative for Sodium Nitrite in Dry Fermented Sausages. Foods 2020, 9, 1066. [Google Scholar] [CrossRef]

- Wan Rosli, W.I.; Habibah, B. The Effect of Bamboo Shoot (Gigantochloa Albociliata) Addition on the Physical Properties and Sensorial Acceptability of Beef Patty. Food Res. 2021, 5, 114–123. [Google Scholar] [CrossRef]

- YueJun, H.; YongDe, Y.; Feng, T.; XueFeng, G.; Jin, W. Chemical Compositions and Antioxidant Capacity of Essential Oils from Different Species of the Bamboo Leaves. Sci. Silvae Sin. 2010, 46, 120–128. [Google Scholar]

- Thomas, R.; Jebin, N.; Saha, R.; Sarma, D.K. Antioxidant and Antimicrobial Effects of Kordoi (Averrhoa Carambola) Fruit Juice and Bamboo (Bambusa Polymorpha) Shoot Extract in Pork Nuggets. Food Chem. 2016, 190, 41–49. [Google Scholar] [CrossRef]

- Chongtham, N.; Bisht, M.S.; Haorongbam, S. Nutritional Properties of Bamboo Shoots: Potential and Prospects for Utilization as a Health Food. Compr. Rev. Food Sci. Food Saf. 2011, 10, 153–168. [Google Scholar] [CrossRef]

| Phytochemicals | Value |

|---|---|

| Total phenolics (µg GAE/mL of BEO) | 1244 |

| Total flavonoid (µgQE/mL of BEO) | 160.53 |

| Fatty Acid | Percentage of Total Fatty Acids |

| Caproic acid (C6:0) | 6.935 |

| Caprylic acid (C8:0) | 3.825 |

| Capric acid (C10:0) | 16.155 |

| Undecylic acid (C11:0) | 21.82 |

| Lauric acid (C12:0) | 1.53 |

| Tridecylic acid (C13:0) | 18.785 |

| Myristic acid (C14:0) | 1.06 |

| Pentadecylic acid (C15:0) | 1.225 |

| Margaric acid (C17:0) | 1.045 |

| Oleic acid (C18:1) | 3.355 |

| In Vitro Antioxidant Potential * | BEO | BHT | BHA | Trolox |

|---|---|---|---|---|

| DPPH scavenging activity | 1.393 ± 0.061 | 13.025 ± 0.244 | 6.754 ± 0.166 | 6.86 ± 0.113 |

| H2O2 scavenging activity | 1.999 ± 0.019 | 85.231 ± 1.136 | 52.466 ± 0.004 | 61.137 ± 0.627 |

| Ferrous ion chelating activity | 0.536 ± 0.002 | 52.933 ± 0.047 | 39.921 ± 0.009 | 46.595 ± 0.180 |

| Nitric Oxide Radical Scavenging activity | 1.615 ± 0.041 | 78.638 ± 0.552 | 69.432 ± 0.185 | 73.645 ± 0.265 |

| Hydroxyl radical scavenging activity | 1.792 ± 0.027 | 82.1945 ± 0.029 | 51.363 ± 0.297 | 69.147 ± 0.376 |

| Superoxide anion radical scavenging activity | 1.232 ± 0.005 | 63.702 ± 0.037 | 39.309 ± 0.028 | 46.242 ± 0.296 |

| Total antioxidant activity | 0.865 ± 0.017 | 70.113 ± 0.147 | 46.846 ± 0.384 | 54.544 ± 0.503 |

| Bacteria | MIC (µL) | MBC (µL) | Tolerance Level | Inference |

|---|---|---|---|---|

| Shigella flexneri | 1.5 | 6 | 4 | Bactericidal |

| Bacillus subtilis | 1.5 | 7 | 4.66 | Bactericidal |

| Klebsiella pneumoniae | 1.5 | 7 | 4.66 | Bactericidal |

| Escherichia coli | 1.5 | 6 | 4 | Bactericidal |

| Staphylococcus aureus | 1.5 | 6 | 4 | Bactericidal |

| Proteus vulgaris | 1.5 | 8 | 5.33 | Bactericidal |

| Vibrio cholerae | 1.5 | 7 | 4.66 | Bactericidal |

| Salmonella Typhimurium | 1.5 | 5 | 3.33 | Bacteriostatic |

| Parameters | Control | BEO-I (T1) | BEO-II (T2) |

|---|---|---|---|

| Emulsion Stability, Cooking Yield, Proximate Composition | |||

| Emulsion pH | 6.10 ± 0.02 | 6.09 ± 0.02 | 6.11 ± 0.01 |

| Emulsion stability (%) | 95.08 ± 0.12 | 95.12 ± 0.14 | 95.02 ± 0.11 |

| Cooking yield (%) | 96.79 ± 0.07 | 97.26 ± 0.09 | 97.83 ± 0.22 |

| Moisture (%) | 68.26 ± 0.64 | 67.86 ± 0.72 | 67.74 ± 0.68 |

| Protein (%) | 15.88 ± 0.44 | 15.92 ± 0.34 | 16.04 ± 0.50 |

| Fat (%) | 13.76 ± 0.49 | 14.06 ± 0.35 | 14.69 ± 0.62 |

| Ash (%) | 1.08 ± 0.49 | 1.12 ± 0.13 | 1.09 ± 0.89 |

| Total phenolics content (mg GAE/g) ** | 0.074 ± 0.16 b | 1.484 ± 0.12 a | 1.852 ± 0.18 a |

| Expressible water (%) | 26.84 ± 1.12 | 25.72 ± 3.00 | 26.96 ± 2.05 |

| Textural Properties of Meatballs | |||

| Hardness (N/cm2) | 42.75 ± 1.07 | 42.45 ± 1.86 | 38.97 ± 1.89 |

| Springiness (cm) | 0.90 ± 0.01 a | 0.89 ± 0.02 ab | 0.87 ± 0.01 b |

| Cohesiveness (ratio) | 0.65 ± 0.02 a | 0.63 ± 0.02 ab | 0.61 ± 0.03 b |

| Gumminess (N/cm2) | 27.27 ± 0.74 a | 27.20 ± 0.97 a | 24.86 ± 0.23 b |

| Chewiness (N/cm) | 24.43 ± 0.75 a | 23.84 ± 0.82 a | 21.72 ± 0.43 b |

| Treatments | Day 0 | Day 5 | Day 10 | Day 15 | Day 20 |

|---|---|---|---|---|---|

| pH | |||||

| Control | 6.14 ± 0.02 e | 6.19 ± 0.01 dA | 6.41 ± 0.01 cA | 6.49 ± 0.01 bA | 6.58 ± 0.01 aA |

| BEO-I (T1) | 6.14 ± 0.01 d | 6.16 ± 0.03 dB | 6.21 ± 0.01 cB | 6.26 ± 0.01 bB | 6.29 ± 0.01 aB |

| BEO-II (T2) | 6.15 ± 0.01 b | 6.17 ± 0.01 abAB | 6.22 ± 0.01 aB | 6.27 ± 0.01 aB | 6.31 ± 0.01 aB |

| Thiobarbituric Acid Reactive Substance (TBARS) Value | |||||

| Control | 0.34 ± 0.01 e | 0.54 ± 0.01 dA | 0.73 ± 0.01 cA | 1.15 ± 0.02 bA | 1.67 ± 0.03 aA |

| BEO-I (T1) | 0.34 ± 0.01 e | 0.38 ± 0.01 dB | 0.45 ± 0.01 cB | 0.54 ± 0.01 bB | 0.73 ± 0.01 aB |

| BEO-II (T2) | 0.34 ± 0.01 e | 0.37 ± 0.01 dB | 0.42 ± 0.01 cB | 0.48 ± 0.01 bC | 0.64 ± 0.01 aC |

| Lightness (L*) | |||||

| Control | 67.63 ± 0.10 | 67.90 ± 0.07 | 68.08 ± 0.15 | 68.25 ± 0.12 A | 68.45 ± 0.08 A |

| BEO-I (T1) | 67.41 ± 0.33 | 67.57 ± 0.28 | 67.67 ± 0.20 | 67.80 ± 0.12 B | 67.94 ± 0.16 B |

| BEO-II (T2) | 67.59 ± 0.15 | 67.78 ± 0.11 | 67.81 ± 0.05 | 67.87 ± 0.14 B | 67.92 ± 0.09 B |

| Redness (a*) | |||||

| Control | 8.31 ± 0.07 a | 8.28 ± 0.05 ab | 8.13 ± 0.04 bB | 7.96 ± 0.04 cB | 7.45 ± 0.07 dB |

| BEO-I (T1) | 8.43 ± 0.10 a | 8.35 ± 0.03 a | 8.30 ± 0.04 aA | 8.27 ± 0.04 abA | 8.15 ± 0.02 abA |

| BEO-II (T2) | 8.32 ± 0.04 a | 8.29 ± 0.02 ab | 8.24 ± 0.02 abA | 8.21 ± 0.04 bcA | 8.14 ± 0.03 cA |

| Yellowness (b*) | |||||

| Control | 18.42 ± 0.08 | 18.40 ± 0.07 | 18.39 ± 0.03 | 18.37 ± 0.01 | 18.36 ± 0.04 |

| BEO-I (T1) | 18.50 ± 0.09 | 18.47 ± 0.07 | 18.44 ± 0.05 | 18.41 ± 0.04 | 18.37 ± 0.04 |

| BEO-II (T2) | 18.32 ± 0.11 | 18.30 ± 0.11 | 18.28 ± 0.10 | 18.24 ± 0.09 | 18.22 ± 0.09 |

| Total Viable Count | |||||

| Control | 2.67 ± 0.03 e | 3.83 ± 0.06 dA | 4.92 ± 0.02 cA | 5.79 ± 0.03 bA | 6.39 ± 0.02 aA |

| BEO-I (T1) | 2.64 ± 0.04 e | 2.87 ± 0.02 dB | 3.17 ± 0.03 cB | 3.79 ± 0.04 bB | 4.13 ± 0.03 aB |

| BEO-II (T2) | 2.61 ± 0.03 e | 2.76 ± 0.03 dB | 3.04 ± 0.04 cC | 3.49 ± 0.03 bC | 4.07 ± 0.06 aB |

| Treatments | Day 0 | Day 5 | Day 10 | Day 15 | Day 20 |

|---|---|---|---|---|---|

| Appearance | |||||

| Control | 6.69 ± 0.04 a | 6.66 ± 0.03 a | 6.22 ± 0.12 bB | 6.06 ± 0.03 cB | 5.41 ± 0.05 dB |

| BEO-I (T1) | 6.71 ± 0.04 a | 6.64 ± 0.03 a | 6.60 ± 0.04 aA | 6.48 ± 0.03 bA | 6.43 ± 0.02 bA |

| BEO-II (T2) | 6.70 ± 0.03 a | 6.62 ± 0.03 a | 6.61 ± 0.04 aA | 6.50 ± 0.11 abA | 6.37 ± 0.06 bA |

| Flavor | |||||

| Control | 7.04 ± 0.16 a | 6.81 ± 0.15 a | 6.25 ± 0.07 bB | 6.06 ± 0.05 bB | 4.94 ± 0.10 cB |

| BEO-I (T1) | 7.05 ± 0.09 a | 6.87 ± 0.06 a | 6.75 ± 0.13 abA | 6.63 ± 0.07 bcB | 6.44 ± 0.05 cA |

| BEO-II (T2) | 7.06 ± 0.05 a | 6.93 ± 0.05 ab | 6.75 ± 0.07 bcA | 6.67 ± 0.06 cA | 6.39 ± 0.09 dA |

| Juiciness | |||||

| Control | 7.01 ± 0.07 a | 6.62 ± 0.09 b | 6.56 ± 0.09 b | 6.00 ± 0.07 cB | 5.40 ± 0.12 dB |

| BEO-I (T1) | 7.03 ± 0.12 a | 6.86 ± 0.11 ab | 6.69 ± 0.10 bc | 6.56 ± 0.09 cdA | 6.37 ± 0.10 dA |

| BEO-II (T2) | 7.09 ± 0.07 a | 6.80 ± 0.07 b | 6.66 ± 0.06 bc | 6.53 ± 0.06 cA | 6.32 ± 0.07 dA |

| Overall Acceptability | |||||

| Control | 6.89 ± 0.10 a | 6.72 ± 0.07 a | 6.19 ± 0.07 bB | 5.66 ± 0.10 cB | 5.25 ± 0.07 dB |

| BEO-I (T1) | 6.95 ± 0.09 a | 6.94 ± 0.12 a | 6.76 ± 0.08 abA | 6.65 ± 0.09 bA | 6.56 ± 0.09 bA |

| BEO-II (T2) | 7.05 ± 0.08 a | 6.82 ± 0.07 b | 6.69 ± 0.07 bA | 6.63 ± 0.06 bA | 6.39 ± 0.07 cA |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Das, J.K.; Chatterjee, N.; Pal, S.; Nanda, P.K.; Das, A.; Das, L.; Dhar, P.; Das, A.K. Effect of Bamboo Essential Oil on the Oxidative Stability, Microbial Attributes and Sensory Quality of Chicken Meatballs. Foods 2023, 12, 218. https://doi.org/10.3390/foods12010218

Das JK, Chatterjee N, Pal S, Nanda PK, Das A, Das L, Dhar P, Das AK. Effect of Bamboo Essential Oil on the Oxidative Stability, Microbial Attributes and Sensory Quality of Chicken Meatballs. Foods. 2023; 12(1):218. https://doi.org/10.3390/foods12010218

Chicago/Turabian StyleDas, Jyotishka Kumar, Niloy Chatterjee, Srija Pal, Pramod Kumar Nanda, Annada Das, Ligen Das, Pubali Dhar, and Arun K. Das. 2023. "Effect of Bamboo Essential Oil on the Oxidative Stability, Microbial Attributes and Sensory Quality of Chicken Meatballs" Foods 12, no. 1: 218. https://doi.org/10.3390/foods12010218

APA StyleDas, J. K., Chatterjee, N., Pal, S., Nanda, P. K., Das, A., Das, L., Dhar, P., & Das, A. K. (2023). Effect of Bamboo Essential Oil on the Oxidative Stability, Microbial Attributes and Sensory Quality of Chicken Meatballs. Foods, 12(1), 218. https://doi.org/10.3390/foods12010218