Sensors, Devices and Systems for Future Food Production and Packaging

A special issue of Micromachines (ISSN 2072-666X). This special issue belongs to the section "E:Engineering and Technology".

Deadline for manuscript submissions: closed (20 March 2022) | Viewed by 28047

Special Issue Editors

Interests: cultured meat manufacturing; alternative proteins; tissue engineering; bioinks; extracellular matrix

Interests: biosensors; microfluidics; cultured meat; cellular agriculture; pathogens

Special Issues, Collections and Topics in MDPI journals

Interests: cultivated meat; fermentation; bioreactors; stem cells; tissue engineering

Special Issue Information

Dear Colleagues,

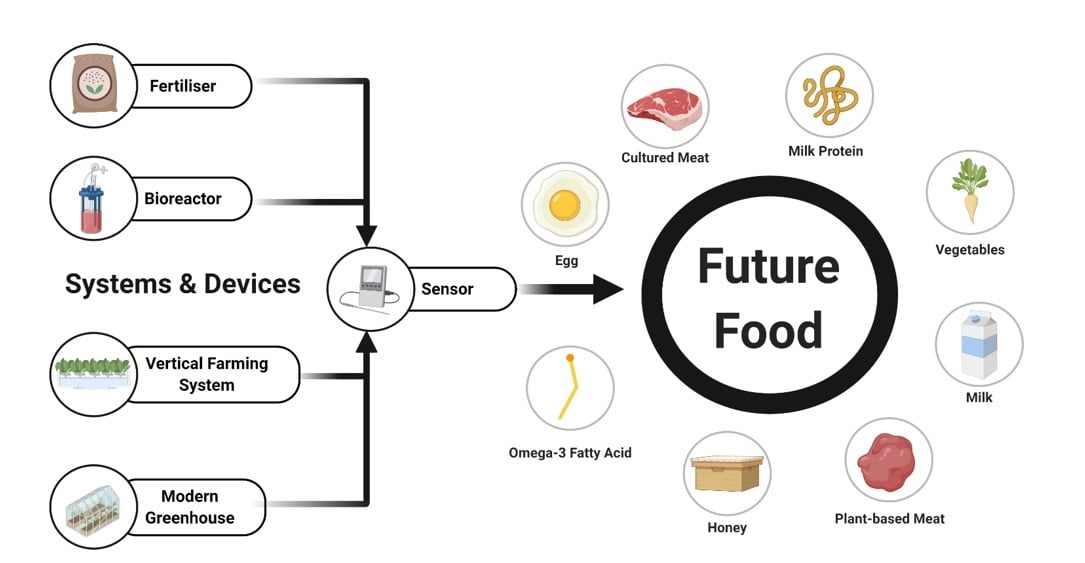

It is our pleasure to invite you to contribute a manuscript to this Special Issue on “Sensors, Devices, and Systems for Future Food Production and Packaging". The United Nations estimates that the global population will reach 9.7 billion by 2050, which will go along with increased urbanization and change in consumer preferences. The rise in caloric demand, as well as aggressive consumption of proteins, will lead to increased exploitation of natural resources, putting tremendous pressure on the environment with catastrophic consequences on climate and global warming. Hence, innovative technologies that can disrupt current means of agricultural produce to enhance productivity with minimal environmental impact are imperative. “Future Foods” is an exciting and emerging area where systems/devices/sensors developed in the fields of biomedicine, tissue engineering, diagnostics, regenerative medicine, cell therapy, etc. could be adapted for growing more, functional, and better foods. One of the major emerging areas under “Future Foods” is developing alternative proteins and components produced by cellular agriculture. Existing bioprocessing technologies are being optimized and further designed to integrate new requirements for alternative protein production. Despite the tremendous recent breakthroughs, most alternative protein categories, including cultured meat/cultivated meat, are yet to achieve their scale-up potential, which is critical to attaining price, and taste parity. Bioprocess optimization research is vital in this particular area that will bolster the scale-up of alternative proteins. Devices, systems, and sensors are the necessary elements of the bioprocess optimization and will prove crucial for the successful scale-up of the sector to industry-level production. Furthermore, sensors, devices, and systems play an essential role in other segments of the future food value chain including packaging, distribution, and storage.

This Special Issue will highlight advances (non-exhaustive list) in the field of:

- Systems for mammalian, avian, insect, seafood cell isolation, enrichment, expansion (bioreactors, types/modes of bioreactors, bioprocess design, microcarrier and scaffolding biomaterials, media recycling options,);

- Systems for the plant, algal, fungal–protein extractions, processing (solubilization, precipitation, heating, extrusion, cooling, texturization,);

- Fermenter/bioreactor design, bioprocess design, feedstock optimization;

- Sensing devices for cultured meat, plant-based meat, insect-based meat, agriculture, vertical farming, food-borne pathogens, food quality, food ingredient quality;

- CFD modeling—computational modelling for optimization of processes and products;

- Food processing systems (product formulation)—3D (bio)printers, flavouring, texturization;

- Industry 4.0—Integration of IoT (during the food manufacturing process for food safety), blockchain (tracing the lifecycle of food products), and AI (sorting food, ensuring hygiene standards, food supply optimization,);

- Packaging—Innovative active and intelligent packaging methods/processes/systems, tracking of food ingredients/finished food products, recycling, and valorization, etc.

Dr. Deepak Choudhury

Dr. Ivana Gadjanski

Dr. Akshay Vishnu Bhat

Mr. Darko Mandich

Guest Editors

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the special issue website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 100 words) can be sent to the Editorial Office for announcement on this website.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Micromachines is an international peer-reviewed open access monthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript. The Article Processing Charge (APC) for publication in this open access journal is 2600 CHF (Swiss Francs). Submitted papers should be well formatted and use good English. Authors may use MDPI's English editing service prior to publication or during author revisions.

Keywords

- Active and intelligent packaging

- Alternative proteins

- Biomaterials

- Bioprocessing

- Bioreactors

- Biosensors

- Cellular agriculture

- CFD modelling

- Cultured meat/cell-based meat/cultivated meat

- Fermentation

- Food 3D (bio)printers

- Food scanners

- Future foods

- Industry 4.0

- Microcarriers

- Plant-based meat alternatives

- Recycling

- Sensors

- Sustainable packaging

- Texturization

- Valorization

Benefits of Publishing in a Special Issue

- Ease of navigation: Grouping papers by topic helps scholars navigate broad scope journals more efficiently.

- Greater discoverability: Special Issues support the reach and impact of scientific research. Articles in Special Issues are more discoverable and cited more frequently.

- Expansion of research network: Special Issues facilitate connections among authors, fostering scientific collaborations.

- External promotion: Articles in Special Issues are often promoted through the journal's social media, increasing their visibility.

- e-Book format: Special Issues with more than 10 articles can be published as dedicated e-books, ensuring wide and rapid dissemination.

Further information on MDPI's Special Issue polices can be found here.